I read the wired article on the Speedfactory at Adidas, via Katheryn Corrick. It is the best articulation of a trend that has been coming for a while: businesses outsourced manufacturing when there is no competitive advantage in it. When I worked at Cisco, in the days of its peak growth and value, it was really a software business, and the hardware was a means to an end. John Chambers (then CEO) created significant advantage for the business by outsourcing almost everything and ‘virtualising’ the business. Fast forward two, nearly three, decades, and almost every major business now outsources their manufacturing, even businesses that are essentially manufacturing businesses.

Two things came with the shift to outsourced, globalised manufacture, both mentioned within the article. The first was the evolution to “two bodies and two minds” – Manufacturing is now a business partner, a separate entity. For the design/marketing part of the business manufacturing are not long your “friends” or co-workers, they are your supplier, and you are their customer. They they have other customers too. And they want to look good. And you want to look good. And your cultures are different. And communication is… Not as good or open as it was. The second is that the shift allowed manufacturing to consolidate, and to shift to monolithic corporate structures in low-wage economies. For the most part, that has meant China. And, for Europe and the US, that means 6 weeks shipping time from the factory to the shop, if you are using container shipping, as most do. The alternative shipping methods are pricy and still take up to a month, putting latency and lag into the business. “Supply Chain Management” has become an art, and more than that, it has become an industry in and of itself, with it’s own innovations like FCL/LCL (‘Full Container Load’/’Less than Container Load’), which have in turn favoured larger slower businesses, over smaller, more nimble ones.

There are certainly innovations, like the China-Europe rail service, which will be disruptive. But not as disruptive as the alternative: near-shoring, or even bringing manufacturing back in-house, local to the market, with new manufacturing processes. From the Wired article:

“In Asia today, it takes between 90 and 60 days to turn these materials into a product,” says Gerd Manz, adidas’s vice president of technology innovation. “Today, if we’re ambitious, we can go from here to final product within… “

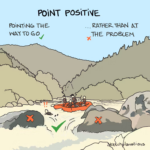

…Days, if not a day. And so the cycle flips. With the advent of the next generation of manufacturing technology (advanced robotics with machine learning) there is an opportunity to gain competitive advantage by insourcing and applying technology to differentiate manufacturing processes. However, to my mind at least, the biggest part of that advantage doesn’t come from having control of the manufacturing, it comes from from having an understanding of it – moving back to “one mind and one body” in the business.

“We thought, goddammit, we’re cooking in the same kitchen with the same ingredients as everybody else,” [Manz] recalls. “All of our competitors have the same board with the same ten spices on it, and because we all go to the same suppliers and get the same catalogue, the only thing that changes is what we pick. So all the soups that come out of this kitchen taste the same, no matter what the brand.”

The issue with outsourcing manufacturing is that your loose sight of the ‘knowledge and craft’ of manufacturing – how did you arrive at the ingredients? What are the limitations on sourcing them? What is hard? What is easy? Why are certain things done or not done? With new ways of manufacturing, using advanced technologies, this knowledge becomes critical. By having knowledge of both the process, and your customer market, you can mine a new and unique set of opportunities.

The one body one mind principle isn’t just limited to manufacturing, it can apply to software development, marketing processes, HR, in fact almost any aspect of the business. Outsourcing business functions can be a blessing for a growing business, but it can also quickly turn in to a curse. I have come across many businesses that have developed blind spots and a form of learned helplessness from outsourcing key functions, just as I have worked with many start ups that have thrived because of it.

One of the reason’s I love working in product management and product marketing is that you are constantly bridging the gaps and looking for the opportunities in the tensions between what people want/buy and what you can/could produce. The game and the skills are about to completely change again. The “Chinese lag” – that 6 week period between when things are ordered and leave the factory in China, and when they hit Europe/USA, has become a fundamental part of the design loop, but it may disappear.

When I moved into the SaaS (software as a service) world, it took quite a bit of adjustment to move from traditional product cycles to one where I could think of a feature, build it, ship it and get customer feedback, all within a single day. Continuous delivery and continuous deployment are new mindsets, with much shorter OODA loops (Observe, Orient, Decide, and Act) – our world is about to get even faster, and even more competitive.